Underground constructions have now become common place, and are frequently requested for a wide variety of purposes: from the construction of new rooms to the redevelopment of existing ones, from the insertion of infrastructures to the creation of parking spaces and garages, the possibilities are many.

But, regardless of their intended use, they still require a rather complicated realisation that needs both technical and regulatory knowledge at its base.

First of all, it is good to make a premise: depending on whether they are designed in more or less congested urban areas, or subject to historical/artistic constraints, they require different types of excavation in terms of depth, size, and intervention techniques which, in turn, influence the choice of waterproofing system.

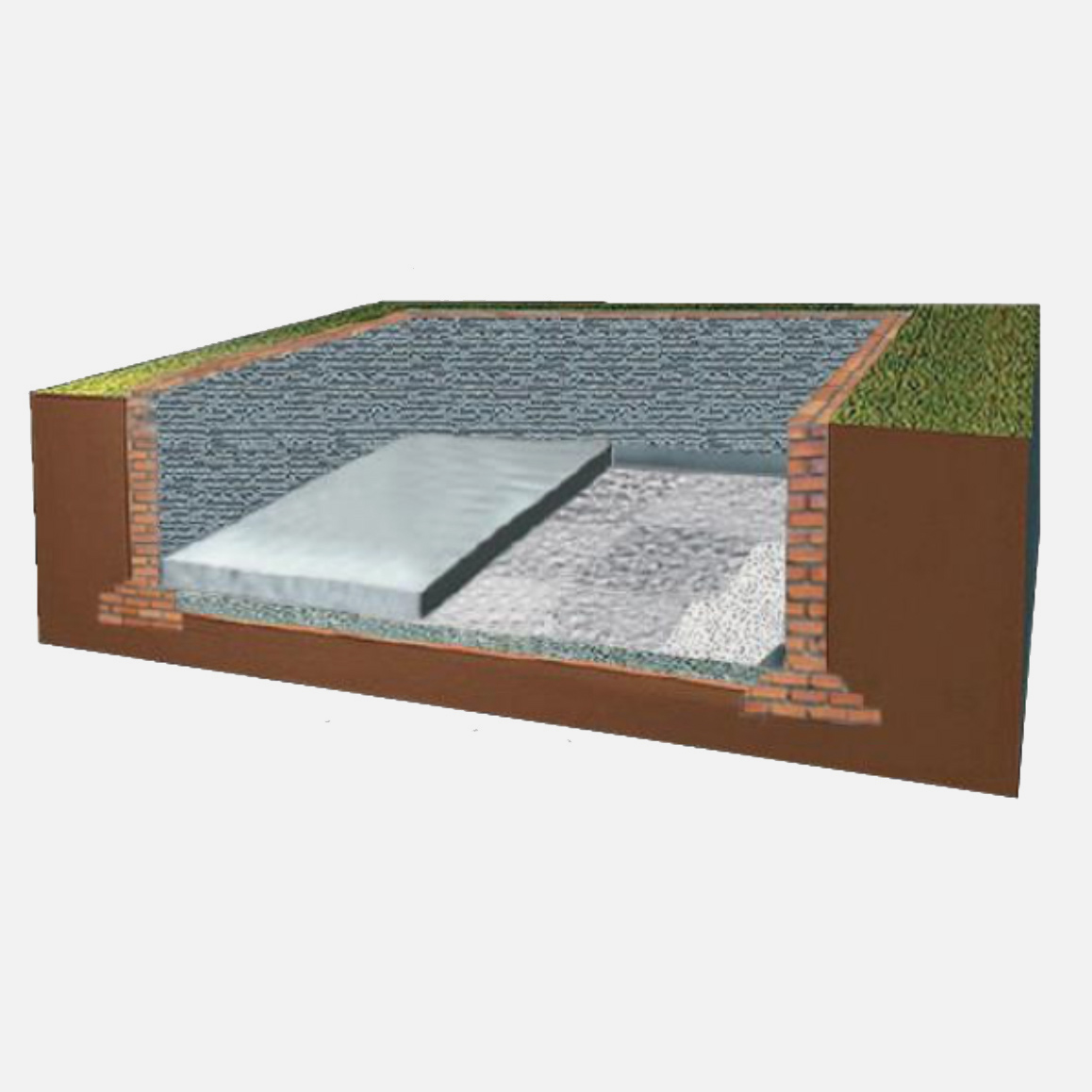

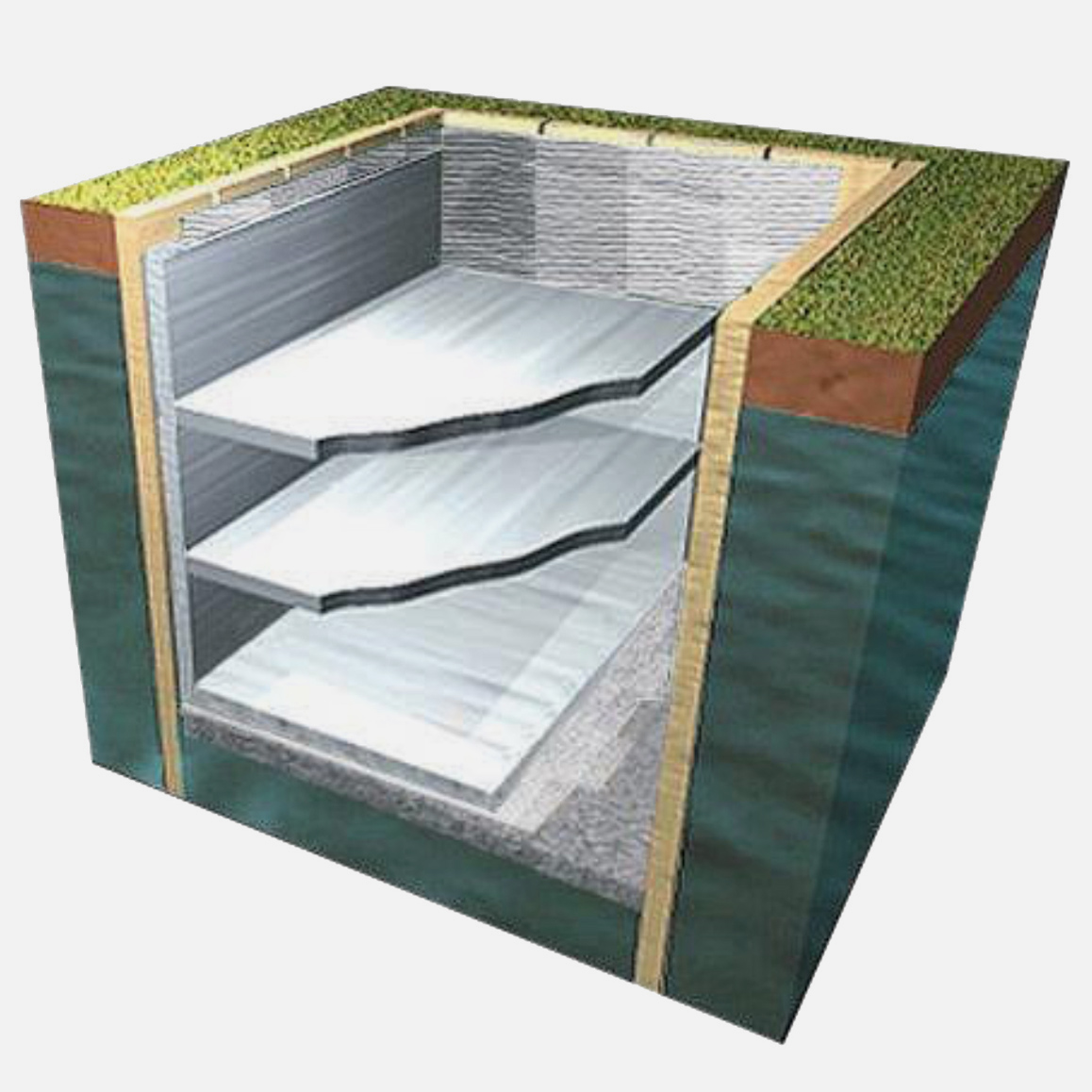

OPEN EXCAVATION

Open excavation, the most traditional system of intervention, is also the most economical as it is simpler than the others, exploiting the natural angle of internal friction of the ground for the stability of the slopes of the excavation.

Basically, it consists of the preliminary execution of a trench in the ground on the bottom of which superstructures, infrastructures and everything else that has been foreseen by the design are then laid.

Construction is carried out from the bottom upwards without any limitations in terms of waterproofing systems to be adopted.

However, open excavation operations are not easily practicable in all realities, such as in historical centres, small towns, particularly busy areas, because they often require a lot of space if the soil bearing capacity is limited.

TANKING

In the event of water infiltration and moisture problems occurring in under-floor rooms, it is a good idea to resort to ‘relining‘.

But what does it consist of? These are excavation operations inside an existing structure that require special attention due to the risk of damaging the load-bearing structures of the building above which they are performed.

As a preliminary step, it is necessary to remove plaster, floors, anything that is interposed between the structure and the water containment system, since the waterproofing must be in direct contact with the reinforced concrete structure itself, which is designed to resist hydraulic thrust.

To effectively waterproof the interior, thick waterproofing plasters, elastic coatings or hydro-expansive membranes can be used.

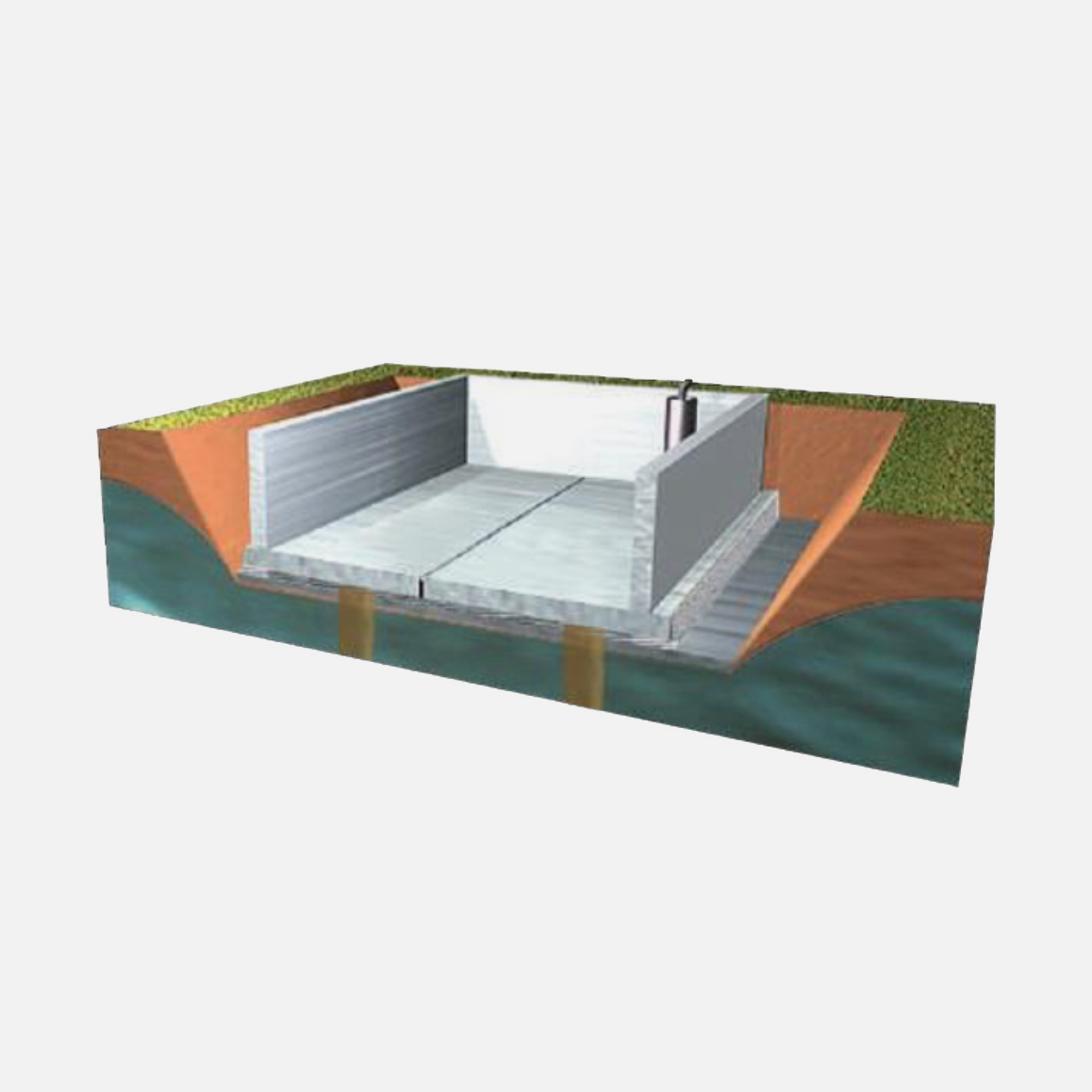

PROVVISIONAL WORKS

Excavation works in partially built-up or particularly congested areas are not a simple matter.

First and foremost, they require the design of works that allow the excavation to be carried out without causing damage to adjacent areas where there are, for example, buildings.

The Bottom Up excavation, in such circumstances, is the most suitable as it involves the construction of a “provisional box”, a kind of support on all sides that will serve both to contain the surrounding soil and to prevent the entry of groundwater, inside which the final structure will then be built.

This box is realised through the use of temporary works intended to waterproof the structure underneath, sometimes recoverable and sometimes not, which may be of three types: diaphragms, piles or sheet piling.

Diaphragms, prefabricated or cast-in-place structures, are considered the best in terms of soil containment and water flow abatement.

The use of rows of piles (piling) driven into the ground without removal of material, or drilled, obtained by prior removal of soil and subsequent casting with cement mix, is also an excellent alternative to create an effective hydraulic barrier.

Finally, sheet piles, placed in sequence, form a continuous vertical wall (sheet piling) inserted at a depth greater than that of the excavation.

They can only be used as an effective water barrier in soils free of rocks, stones or other elements that may prevent them from being mechanically driven into the ground.

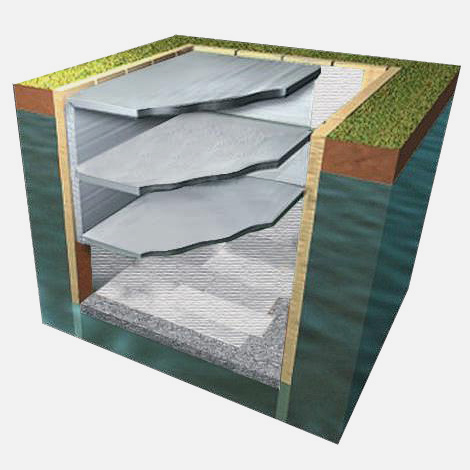

TOP DOWN

In complex urban areas and historic city centres, the Top Down excavation procedure is definitely the best, as it allows for the rapid construction of underground spaces without encroaching on external areas and/or damaging existing buildings located in the vicinity of the excavation.

The scheduling of works changes. You start from street level instead of the foundations, thus reversing the organisation of the work.

The execution of the work begins with the construction of the diaphragms, which will become the outer walls of the reinforced concrete box that will act as support for the surrounding soil, and which will be immediately waterproofed.

In this way, construction and waterproofing begins from the top, gradually proceeding downwards to the benefit of the part on the surface, which becomes usable again in a short time.